What is process cooling?

Process cooling refers to techniques and systems used to remove excess heat generated during industrial processes, ensuring optimal operating conditions for equipment and products. Process cooling plays an important role in a number of industries, including manufacturing, chemical processing, food and beverage and pharmaceuticals.

The main purpose of process cooling is to maintain specific temperature ranges for machinery, products and materials, avoiding overheating that can lead to equipment failure, reduced efficiency or compromised product quality.

Key components in process cooling

Cooling systems: These include chillers, cooling towers and heat exchangers. Chillers cool down liquids using mechanical cooling, while cooling towers disperse heat into the atmosphere. Heat exchangers transfer heat between two or more fluids without mixing them and keeping them separated.

Refrigerants: These are substances used in refrigeration systems to absorb heat. The choice of refrigerant can affect efficiency and environmental considerations. We use a environmentally friendly (R32) in many of our units.

Pipes and distribution: A network of pipes transports the cooled liquids to different parts of the plant and ensures that all relevant equipment is adequately cooled.

Control and monitoring: Advanced sensors and control systems monitor temperatures and flow rates, enabling automated adjustments to maintain the desired cooling level.

The importance of process cooling

Efficiency: Proper cooling maximizes the efficiency of industrial processes, reducing energy consumption and operating costs.

Security: By preventing overheating, process cooling helps to ensure the safety of personnel and equipment.

Quality control: Maintaining the correct temperatures prevents product defects and ensures consistent quality.

Compliance with regulations: Many industries are subject to strict regulations on temperature control and emissions, making efficient cooling systems essential.

In short terms, process cooling is an important aspect of many industrial operations, contributing to efficiency, safety and product quality. Properly designed and maintained cooling systems are critical to the smooth running of modern manufacturing and process facilities.

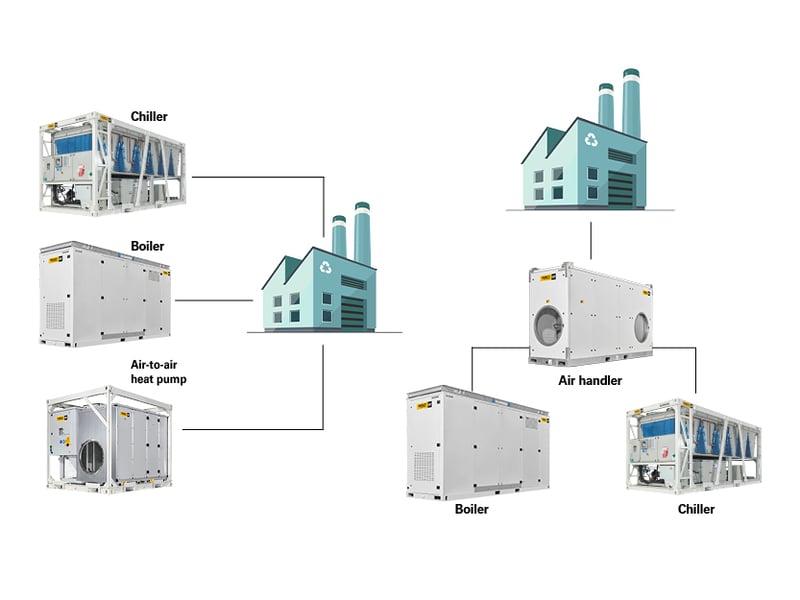

- Our equipment for process cooling

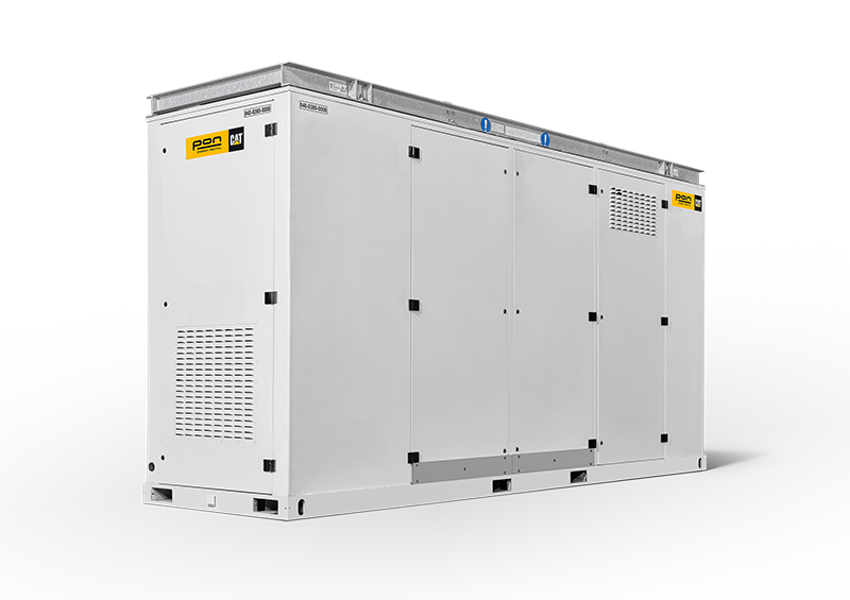

Chillers

• 50 kW - 800 kW

• All-electric rental solutions

• Internal pump

• Canopy or containerized

• High energy efficiency

• Used stand alone or with multiple units.

• Remote monitoring

Hot water systems

• 380 - 600kW

• Temperature range up to 90°C

• Used stand alone or with air handling units

• Diesel, HVO, GTL or gas

• Easy to transport and control.

• Remote monitoring

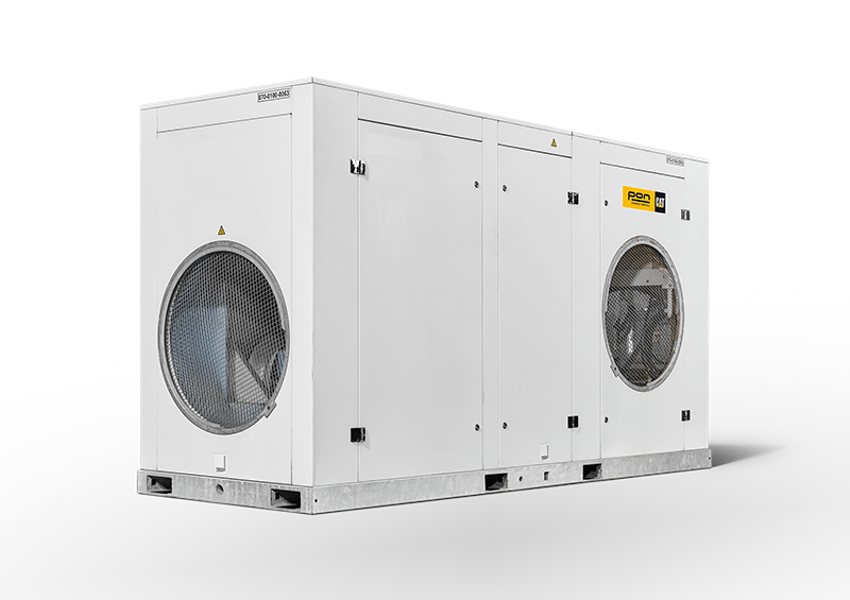

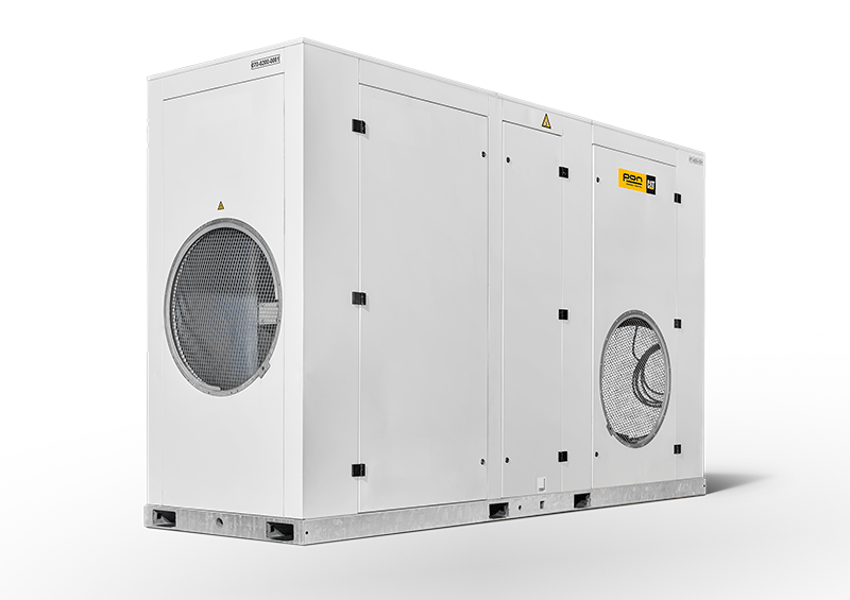

Air-to-air heat pumps

• 50-100kW

• All-electric rental solutions

• Used stand alone or with multiple units.

• Heating and cooling in one single unit

• Easy to transport and control.

• Airflow monitoring and control

• Remote monitoring

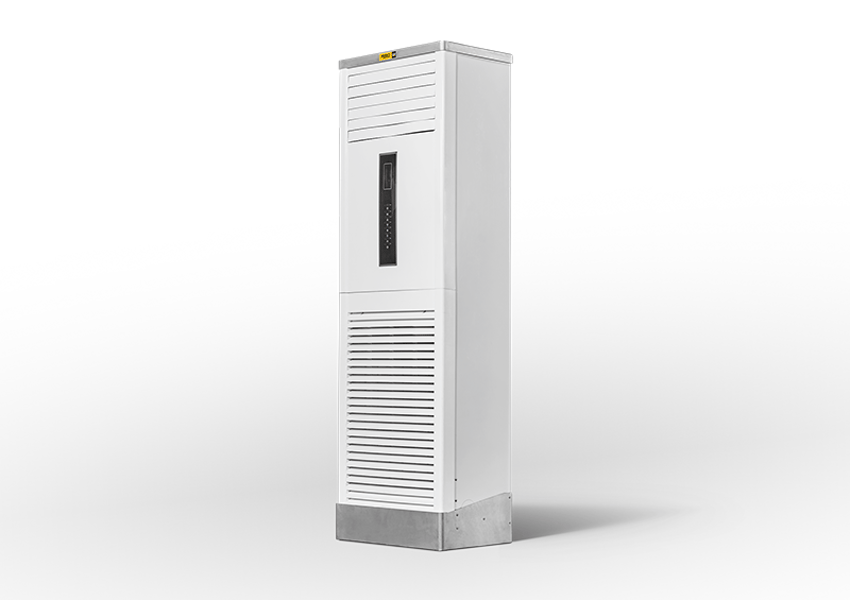

Air handlers

• 20 - 200kW

• Used with cold water systems

• Easy to transport control.

• Temperature range from -12°C to 50°C