Load testing is performed to evaluate and validate the performance and capacity of the engine. Normal load, peak and overload of the equipment can be simulated. The aim of load testing is to ensure that the equipment can handle the expected load and that the engine functions satisfactorily.

Load testing usually involves subjecting the equipment to the maximum rated load or more for a specified period of time. This can be executed using load banks, with resistive and inductive loads, or by connecting the equipment to the actual power source. Equipment performance, stability and temperature rise are measured and monitored throughout the testing process.

Key parameters that are evaluated during a load test include voltage regulation, stability, response time, hot run, vibration, and leakage. This helps to identify any performance issues, such as voltage drop, instability, overheating or inadequate supply dimensioning. The findings in a load test can show if any components need adjustments or if more work is required before the machine is put into use, preventing unforeseen malfunctions or critical failures.

Load testing can prevent critical problems

Load testing of electrical equipment is an important part of maintenance routines and a way to ensure that the machine can continue delivering full capacity without malfunction. It is very important to test equipment used in emergency situations, as these are often started when performing inspections where there is no indication of whether the equipment can deliver stable and sufficient capacity or not. Examples include generators, transformers, switchgear, UPS systems, turbines, motors, and other power distribution systems. Load testing helps to ensure the reliability, safety, and efficiency of these systems, especially during peak loads or in emergency situations. Pon Energy Rental has the equipment and qualified personnel to perform such tests according to the equipment supplier’s maintenance requirements.

How we perform load tests

We perform load testing with our own load banks, and we have a fleet of load banks ranging from 200kVA to 6250 kVA. After the test is performed, a report who can be downloaded is created. Our load banks can perform load tests on electrical equipment both onshore and offshore, and our newest load bank can perform load tests on 690V equipment without the use of a transformer. Our load banks can test stepless from 1kVA/kW to the load bank’s maximum capacity and simulate desired load scenarios.

If the power requirement of the machinery who needs testing is greater than 6MVA, we can tailor a solution by aligning one or more of our load banks, preferably in combination with our high-voltage transformers, to achieve the desired power and voltage level up to 23kV.

Load testing should be performed at regular intervals, especially after installation, maintenance, or modification of electrical equipment. It is essential to ensure safe and reliable operation of electrical systems, prevent equipment malfunction and minimize the risk of electrical hazards.

Some of the most common reasons for performing load testing are:

- Validate that equipment performance is in relation to specifications.

- Assess the impact of the load on various system components, such as cables, cooling systems, voltage- and frequency regulators, etc.

- Identify any problems or weaknesses in equipment design or operation.

- Verifying that the power supply is adequate and assessing the need for additional equipment or upgrades.

- Testing backup power systems, such as emergency generators or UPS, to ensure they can handle the required load in the event of a power failure.

- Compliance with regulatory standards and industry best practice.

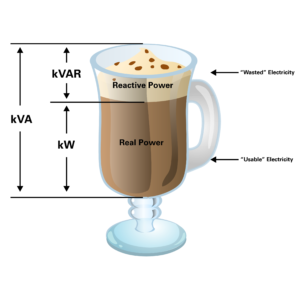

What is kW, kVA and kVAR?

kW stands for kilowatt, which is a unit of power and measurement of real power: 1 kW = 1000 watts (W). kW is used to measure the rate at which energy is generated or consumed in an electrical circuit, power is expressed in watts (denoted W, kW, MW)

kVA is a unit of apparent power: it tells you the total amount of power used in a system. In a 100% efficient system, kW = kVA. However, electrical systems are never 100% efficient and therefore not all the system’s apparent power is used for efficient work. Power is expressed in volt-amperes (denoted VA, kVA, MVA)

kVAR is a unit of measurement of reactive power: In simpler terms, reactive power is the unused power generated by reactive components. An example would be asynchronous motors (induction motor) that need applied power to generate an electromagnetic torque to drive the rotor. The energy used to “magnetize” the motor is not used for the actual work the motor performs and is wasted or unused energy. The power is expressed in reactive volt-amperes (denoted VAR, kVAR, MVAR)

What is the relationship between kW, kVA and kVAR?

Electrical efficiency is expressed as a power factor between 0 and 1: the closer the power factor is to 1, the more efficiently kVA is converted to useful kW.

Apparent power (kVA) consists of two types of power combined: active power (kW) and reactive power (kVAR).

Generators have a typical power factor of 0.8 – and with load banks from Pon Energy Rental, you can regulate and test your system with a power factor from 0.1 to 1.

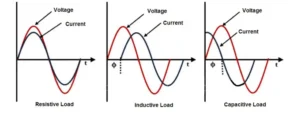

Resistive and Reactive loads

Resistive loads are simple loads where the sine waves of current and voltage are in phase with each other. Resistive loads are often referred to as active or real power, where the power factor is equal to 1. Examples of resistive loads include heating elements and incandescent lamps.

Reactive loads are somewhat more complex and can be either inductive or capacitive. Reactive power is not consumed energy but consists of energy stored in the form of electric and magnetic fields. With a capacitive load, reactive power is added, which provides a leading power factor. Whereas with an inductive load, reactive power is consumed, resulting in a lagging power factor.

With inductive loads, the current and voltage are out of phase with each other. The sine wave for current is offset from the voltage curve, giving a positive kVAR. Examples of devices with inductive loads include asynchronous motors, electromagnets, transformers, rectifiers, and lighting fixtures.

With capacitive load, the sine wave of current is shifted ahead of the voltage curve, giving a negative kVAR. Examples of devices with capacitive load can be synchronous motors, capacitor banks, power factor correctors and powergrid lines.

Pon Energy Rental’s rental fleet includes both resistive load banks and combi load banks, consisting of both resistive and inductive elements. This allows us to regulate the power factor as needed and desired. We can run simple stepwise kW and kVA surcharges or larger MW and MVA surcharges to meet your load testing needs.

Contact us for more information about our load tests.

Back to overview