An efficient temperature control solution is crucial for manufacturing processes, since this can have an influence on points like cycle times, quality, production costs and energy consumption.

It’s essential for the industry to maintain proper heating, cooling, and air conditioning systems to have optimal conditions because it can make a difference in profitability and efficiency, especially over time.

Food, beverages, medicines, and many other products need to be manufactured in specific conditions to get an approved and secure final product. If the temperature conditions are too low or too high, it can lead to a waste of materials and a negative effect on the final product. For example, when producing food, the lack of proper temperature control can make the final product unsafe or even hazardous.

Without an efficient and reliable temperature control solution, entire production lines can fail which can have an impact on the health and safety of employees and the rest of the population since it can cause a lot of catastrophic incidents. Large variations of temperature can lead to dangerous situations like the spread of toxic gases, explosions, fire, and material damage.

Temperature control is vital not only for your machines but also for your workers

As you know, employees will be more productive if they are happy and comfortable in the workplace. The workers can slow down if the temperature on the manufacturing line is too cold, and cold temperatures can affect their motor control and increase the chances of accidents. On the other hand, if the temperature is too hot, the workers can be fatigued and uncomfortable. This can influence productivity and most importantly safety.

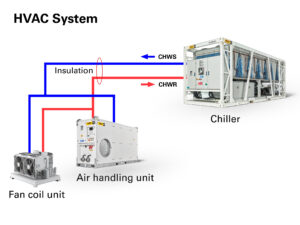

Using equipment such as chillers and heat pumps to regulate levels of temperature and capacity for industrial settings

We can use a variated range of equipment for temperature control applications, for example chillers for production of cold water and hot water systems or boilers for production of hot water. We can combine the units with air handlers for ventilation and temperature control of the industrial space, and equipment like heat pumps which can do both cooling and heating depending on the application.

For that reason, it’s important that the machines are equipped with remote controllers, so that we can adjust the setpoints of the machines and receive alerts if it needs to be adjusted and monitor them by distance.

Heat exchangers are also an important element in temperature control applications. They can run hot and cold process fluids separated by a wall to prevent the mixing of them or the possibility of direct contact.

The principal is to transfer heat from the primary to secondary side. This can be used for heating, cooling and to prevent contamination.

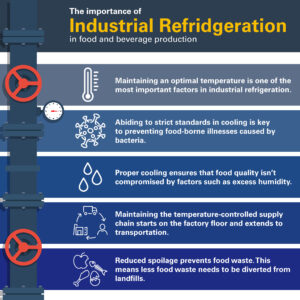

Heating and cooling systems are essential for industrial processes like manufacturing, processing, transportation, and food storage. With the right temperature control solution, we can increase the efficiency of equipment and materials, achieve optimal industrial performance, and improve the quality of the final product. The last point is particularly important for industries like food and beverage for example.

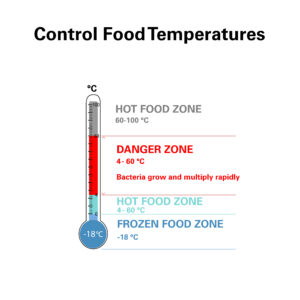

Using temperature control solutions in the food and beverage industry minimizes the potential of growing harmful bacteria and keeps food entirely out of danger zone. The heat will kill the bacteria and the cold temperature slow down the growth of bacteria which prevents it to reach harmful levels.

In the production and preparation of food it’s necessary to follow food safety guidelines for temperature control, to preserve quality but mostly for safety. The food safety standards specify that food needs to be stored and transported at safe temperatures.

On a range of 20-45°C (68-133°F), the most common food-related bacteria can grow and multiply faster. This temperature range is called the danger zone. The fastest rate of growth is around the temperature of the human body, around 37°C.

However, the bacteria can grow and survive from 5-65°C (41-149°F). By using a temperature control solution, we can keep food out of the danger zone. Safe temperatures are considered 5°C (or colder), or 60°C (or hotter).

Regularly checking the temperature of storage areas and products ensures that high standards are maintained in the food manufacturing business. Besides harmful bacteria, all the products must be fresh and safe for as long time as possible, so they don’t need to be thrown away.

Contact us to find our rental solutions for temperature control for industry like food and beverage.

Back to overview